Language

▼

Language

▼

More Language

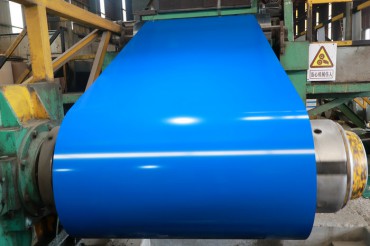

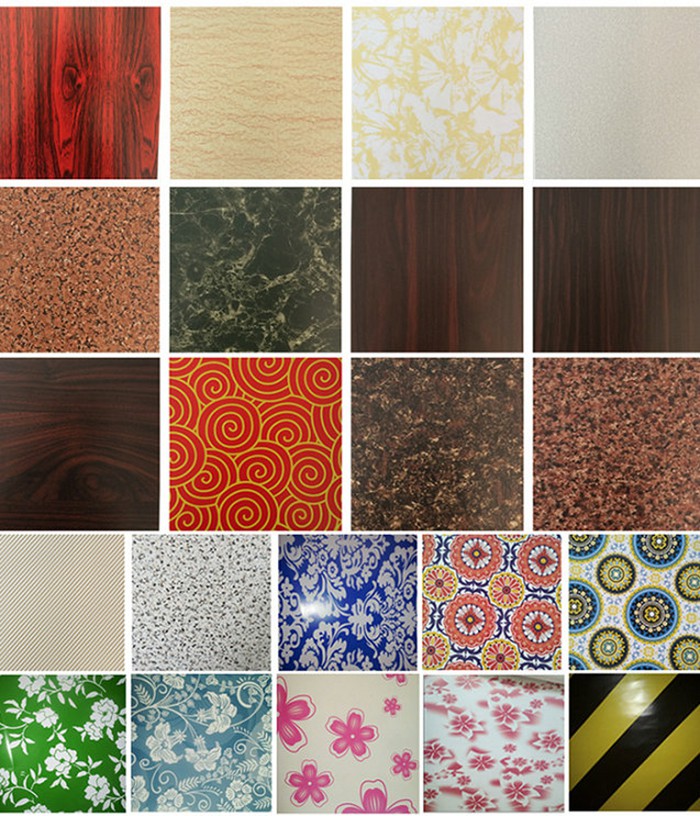

Color steel plate is refined by chemical pretreatment, initial coating, fine coating and other processes. The coating quality is far more uniform, more stable and more ideal than the quality of single piece spraying or brushing on the formed metal surface. Color steel plate with excellent decorative, formability, corrosion resistance, coating adhesion is strong, can maintain long-term color novel. Because the color coated steel plate can obtain good economic effects such as replacing wood with steel, efficient construction, saving energy, preventing pollution, etc., it has become an ideal material for making and selecting building plates.

The influence of the use environment on the color steel plate

1. Environmental factors of corrosion

Longitude and latitude, temperature, humidity, total radiation (UV intensity, sunshine duration), rainfall, pH, wind speed, wind direction, corrosive fallout (C1, SO2).

2. The influence of sunlight

Sunlight is an electromagnetic wave, according to the energy and frequency of the high and low divided into gamma rays, X-rays, ultraviolet, visible light, infrared, microwave and radio waves. Among them, the ultraviolet spectrum (UV) is a high-frequency ray, which has a greater destructive power than the low-energy spectrum, such as the skin spots we know are caused by the sun's ultraviolet rays. UV can also break the chemical bonds of a substance, causing it to break, depending on the wavelength of the UV and the strength of the chemical bonds of the substance. X-rays have a penetrating effect, and gamma rays can break chemical bonds and produce free charged ions, which are deadly to organic matter.

3, the influence of temperature and humidity

For metal coatings, high temperature and high humidity contribute to oxidation reaction (corrosion). When the color coated board is in high temperature environment for a long time, the paint molecular structure on the surface of the color coated board is easy to be damaged, which affects the service cycle. When the humidity is high, the surface of the plate is easy to condensation, and the trend of electrochemical corrosion is enhanced.

4, the impact of pH on corrosion performance

For metal coatings (zinc or aluminum), they are all amphoteric metals, and strong acids and bases can corrode them. However, different metal acid and alkali resistance has its own characteristics, galvanized plate alkaline resistance is slightly stronger, aluminum zinc acid resistance is slightly stronger.

5. The impact of rain

The corrosion resistance of rain to color coated panels depends on the structure of the building and the acidity of the rain. For buildings with large slopes (such as walls), rainwater has a self-cleaning function to prevent further corrosion, but if the injection molding slope is small (such as roofing), rainwater will be deposited on the surface for a long time, promoting the hydrolysis of the coating and water penetration. For the joints or cuts of the steel plate, the presence of water increases the possibility of electrochemical corrosion, and the orientation is also important, and the acid rain situation is more serious.