Language

▼

Language

▼

More Language

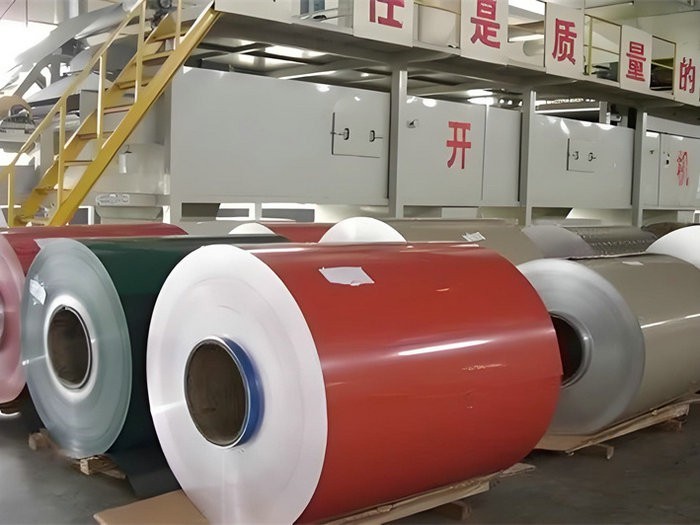

The production process of color coated sheet coil is a complex and delicate process, mainly including the following steps:

After the color coated substrate is put online, the first step is to perform the unwinding operation, unfold and sew the substrate onto the previous substrate to achieve continuous production. This step ensures the continuity and stability of the production process.

Pre treatment is a key step in the production of color coated sheet coils, mainly including degreasing cleaning and chemical pretreatment.

2. Chemical pretreatment: Chemical treatment is carried out on the surface of the substrate, such as roller coating with passivation solution, to improve the adhesion and anti-corrosion ability between the substrate and the coating. After the passivation solution is dried, the initial coating is carried out, which is roller coating primer.

2. Coating and curing of topcoat and backcoat: After the primer is cured, precision coating is carried out, that is, roller coating of topcoat and backcoat. Both topcoat and back coat require drying and curing. This step ensures the quality and durability of the coating.

The painted and cured color coated sheet coil needs to be cooled to ensure the stability and performance of the coating. After cooling, the color coated plate roll is rolled up for subsequent processing and use.

During the production process, it is also necessary to inspect the appearance and performance of the color coated sheet coil to ensure that the product quality meets the standards. After passing the inspection, it will be divided into rolls according to customer needs to meet the requirements of different specifications and uses.